When did levis start outsourcing

Introduction

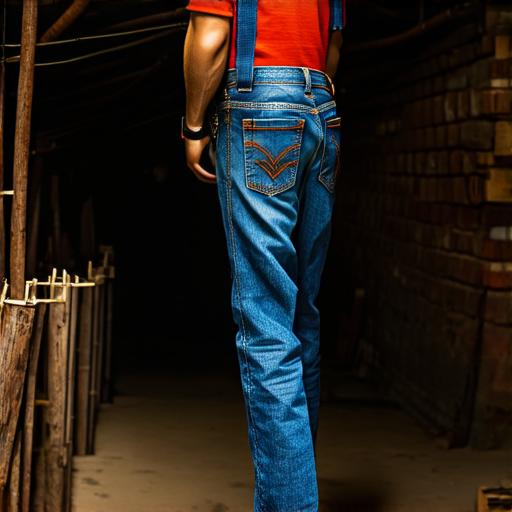

Levi’s, the iconic denim brand, has been in business for over 165 years. Throughout its history, the company has faced numerous challenges, including intense competition from other denim brands and changes in consumer behavior. In response to these challenges, Levi’s has pursued a variety of strategies, including outsourcing.

The Rise of Levi’s Outsourcing Strategy

In the early 2000s, Levi’s began to experience a decline in sales, which it attributed to high prices and outdated designs. To address these issues, the company launched a new strategy that focused on cost-cutting measures, including outsourcing. By outsourcing production to countries with lower labor costs, Levi’s hoped to reduce its production costs, increase efficiency, and stay competitive in the marketplace.

The initial success of this strategy is evident in the fact that Levi’s was able to significantly reduce its production costs, which allowed the company to offer competitive pricing while maintaining high-quality products. Additionally, outsourcing enabled Levi’s to take advantage of new technologies and manufacturing methods, which improved the speed and efficiency of production.

The Fall of Levi’s Outsourcing Strategy

Despite its initial success, Levi’s outsourcing strategy began to falter in the mid-2000s. The company faced a number of challenges that undermined its ability to maintain quality control and sustainability. One major issue was the lack of transparency and accountability in the supply chain.

Another challenge was the impact of global economic conditions on the supply chain. As the global economy slowed down in the mid-2000s, many suppliers struggled to meet Levi’s production targets, leading to delays in delivery and increased costs. Additionally, rising labor costs in some countries made it increasingly difficult for Levi’s to maintain its cost advantage over competitors.

The Impact on Quality, Cost, and Sustainability

The challenges faced by Levi’s outsourcing strategy had a significant impact on the company’s quality, cost, and sustainability. While outsourcing did allow Levi’s to reduce production costs in the short term, it also led to a decline in product quality, which ultimately hurt the company’s reputation and sales.

In addition, the lack of transparency and accountability in the supply chain made it difficult for Levi’s to maintain sustainable practices, such as using environmentally friendly materials and reducing waste. This undermined the company’s efforts to position itself as a socially responsible brand, which is increasingly important to consumers.

Lessons Learned from Levi’s Outsourcing Strategy

Levi’s outsourcing strategy serves as an important cautionary tale for other companies considering this approach. While outsourcing can be a cost-effective way to improve efficiency and reduce production costs, it is important to carefully consider the potential risks and challenges.

Without direct oversight of production facilities, it can be difficult to ensure that suppliers are meeting high standards for quality and sustainability. Additionally, global economic conditions can have a significant impact on the supply chain, making it difficult to maintain cost advantages over competitors.

To avoid repeating Levi’s mistakes, companies should carefully consider their outsourcing strategies and develop robust supply chain management systems that prioritize quality control, transparency, and sustainability. This may involve investing in technology and infrastructure to monitor production processes remotely, or developing partnerships with suppliers who share the company’s values and commitment to ethical practices.

Conclusion

Levi’s outsourcing strategy was a bold attempt to address the challenges facing the company in the early 2000s.